Welcome to the official website of Shenzhen Yinsu Intelligent Technology Co., Ltd.

National Service Hotline:+8618927439160 / +86-755-84118220

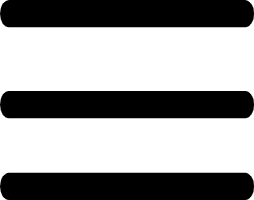

Pebble smart watch V6 review

- Time of issue:2021-05-13

Pebble smart watch V6 review

(Summary description)Customer Name: V6

Assessment times: the first assessment

Review: Xie Yong* Tel: 13686055*** Q Q: 610659***

Email: xieyongchao88***@163.com

Prepared Date: 2021.07.26

- Time of issue:2021-05-13

Customer Name (Customer Project): V6

Assessment times: the first assessment

Review: Xie Yong* Tel: 13686055*** Q Q: 610659***

E-mail: xieyongchao88***@163.com

Prepared Date: 2021.07.26

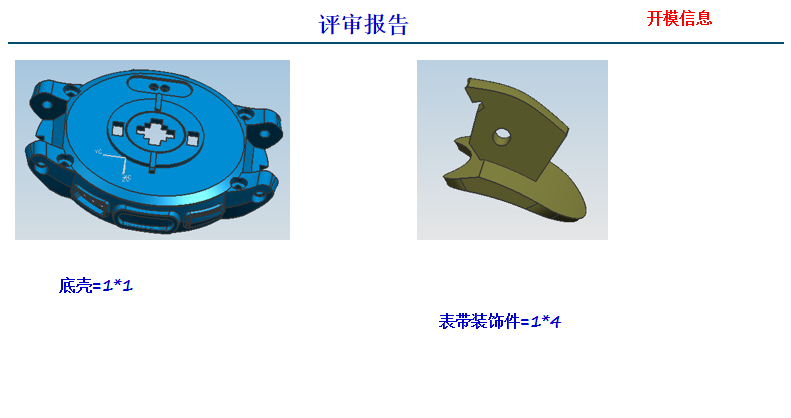

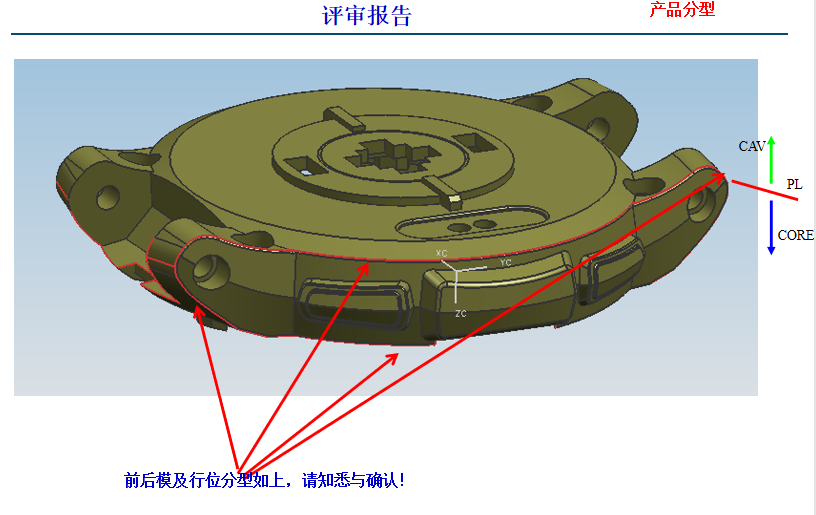

■ 1. Product classification and clamping line review (including front and rear molds, row clamping lines, etc.) Complete machine clamping line diagram ;

1.1 The difference between the front and rear mold divisions is about 0.05

2.2 The row position classification segment difference is about 0.03

3.3 The thimble is less than 0.05 below the glue plane

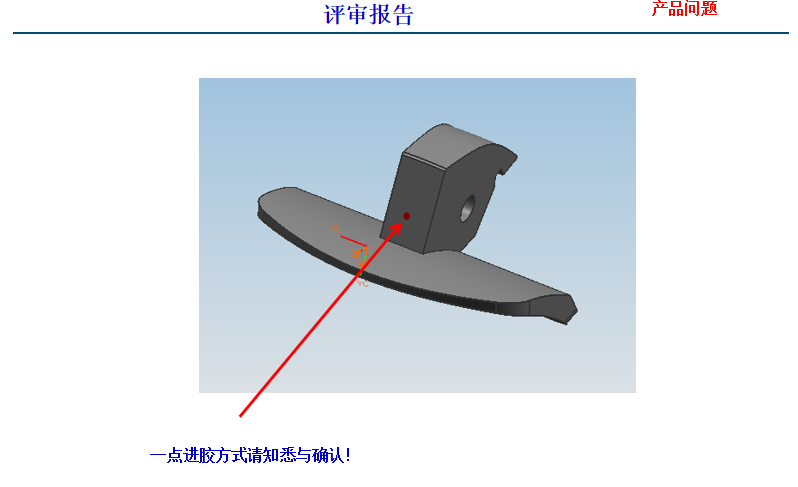

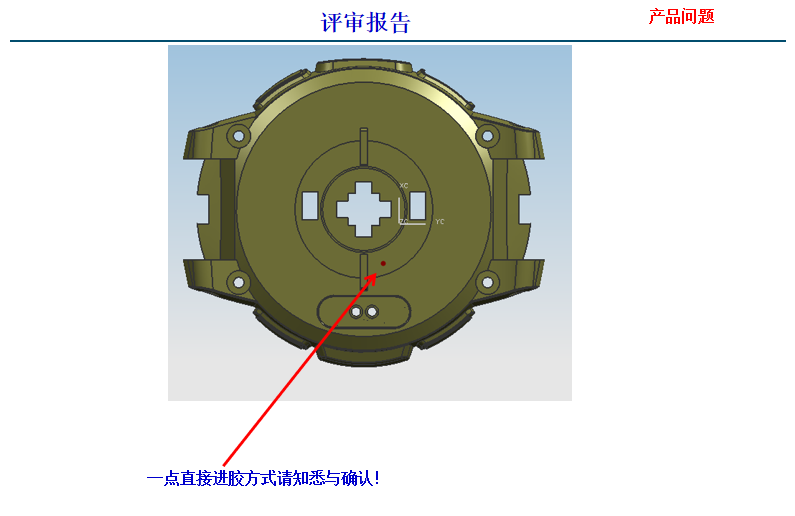

■ 2. Product gate location analysis (including the position of the glue, type, etc.)

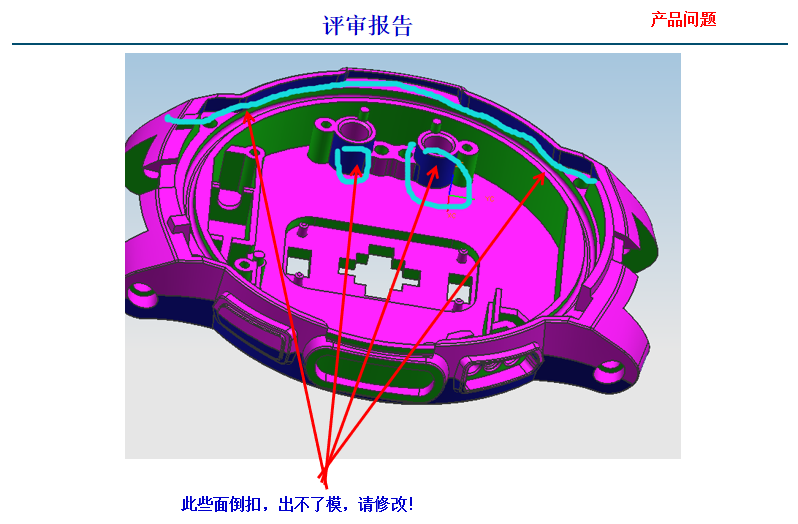

■ 3. Product draft analysis (including analysis of front and rear molds, row position, oblique top direction, etc.)

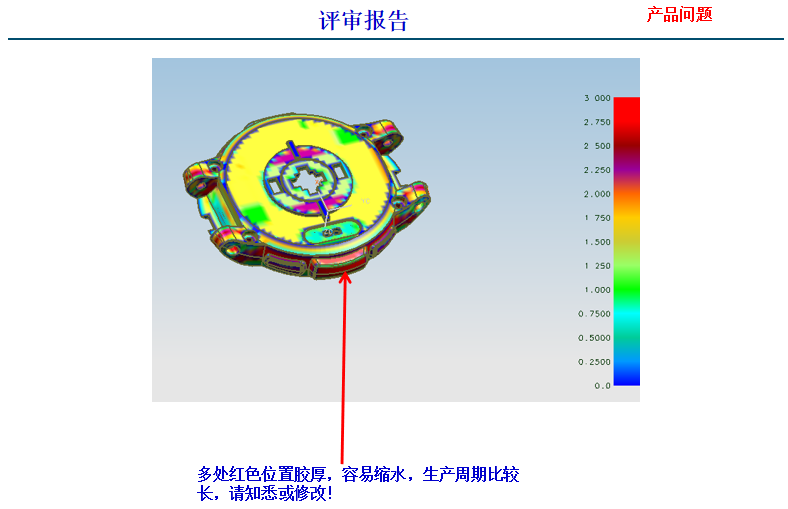

■ 4. Glue thickness analysis (including thick, thin, uneven thickness, etc.)

■ 5. Lettering review■ 6. Mold structure review (including mold structure, steel strength analysis, etc.)

■ 7. Product selection and surface requirements (including materials, number of holes, surface treatment, etc.)

■ 8. Product assembly structure review: Complete machine assembly gap review

8.1 Gap between the two shells after assembly ( 0.05mm ) p>

8.2 Battery cover and back shell (0.15mm recommended) < /span>

8.3 The amount of engagement of the two shells (recommendation: 0.45 for the bottom surface; 0.2mm for the bottom power )

■ 9. Mass production evaluation

■ 10. Required information

|

Product size |

Guest reply (please select) |

|

1. Are the 3D images the size of the material or the size of the finished product? |

material size finished product size |

|

2. If 3D is the size of the material, open the mold according to the 3D number plus the subsequent film thickness such as spraying or vacuum plating, that is, the product image will increase the corresponding film thickness size |

Confirm this plan |

|

3. If 3D is the size of the finished product, please modify the 3D according to the surface technology of the product when opening the mold to subtract the film thickness of surface spraying or vacuum plating |

Confirm this plan

|

|

4. Such as before and after mold opening the product material and product surface process change, resulting in dimensional changes. Its responsibility is not in the mold shop |

Confirm this plan

|

|

General film thickness data and modified 3D glue reduction |

|

|

UV paint: single side film thickness 0.03MM |

3D size unilateral rubber reduction 0.05MM, mainly including TP frame, key hole, side key hole and shape |

|

Vacuum plating: single side film thickness 0.05MM

|

|

|

Rubber paint: single side film thickness 0.05MM |

|

|

Other size requirements (please clearly indicate the mark) |

|

National Service Hotline

+8618927439160

Phone:+8618138419185 / +8618927439160

Tel:+86-755-84118220

Mail:yinsukj@163.com

Address: Room 404, Longsheng Times Building, Gongye West Road, Longsheng Community, Dalang Street, Longhua District, Shenzhen

Official Account

Customer Service